Rheinmetall: Production, Development and Testing

Visit to the Citadel of Hungarian Arms Industry

Text: Eszter Bányász | Photo: Ákos Pintér | 14:33 April 8, 2024The personnel of the HDF 30th Mechanized Infantry Brigade got a unique insight into the domestic production process of the Lynx infantry fighting vehicle while visiting the Rheinmetall plant in Zalaegerszeg on 3 April.

A cornerstone of the National Defence and Armed Forces Development Program’s success – besides procuring state-of-the-art equipment meeting the challenges of the age – is the renewal of the Hungarian defence industry that guarantees the continuity and sustainability of long-term armed forces development. A basis and citadel of this is the Zalaegerszeg-based Rheinmetall Hungary Zrt., which rolled out the first KF41 Lynx infantry fighting vehicle in late 2023, within three years after the ground-breaking ceremony.

“As a result of the newest manufacturing and product technologies applied by the expert Hungarian staff, state-of-the-art vehicles are being handed over to the Hungarian Defence Forces. To get a view of performance and possible future developments, it is important to understand the complexity, modularity and testing processes of next-generation vehicle types” – emphasized Andreas Baumeier, chief operations officer of Rheinmetall Hungary Zrt. related to the significance of production.

The soldiers from Hódmezővásárhely had the opportunity to learn about the details of the production during their visit to the Hungarian plant of Rheinmetall Hungary Zrt., which is unique in size and applied special technologies in Europe and within the Rheinmetall Group. Besides learning about quality control built into the production process, they had the opportunity to see how the newest welding, machining, internal logistics and final assembly technologies are applied.

Another important part of the tasks at the plant is related to post-production service and training. This includes the maintenance of delivered vehicles, the repair of vehicles, equipment and components, the developments based on user feedback, the installation of new components for future developments and the related training. These upgrades are possible because of the modular construction of the Lynx, which provides mechanical and electronic growing potential for decades.

Producing infantry fighting vehicles labelled as “the crown jewellery of the Hungarian armed forces development” is not the only aim, as utilizing the modular construction of the family of the fighting vehicle, other variants of the vehicle will also be produced in Hungary, such as the field ambulance, reconnaissance and command vehicle types, among others. The first units of the latter two are planned to be delivered in 2025.

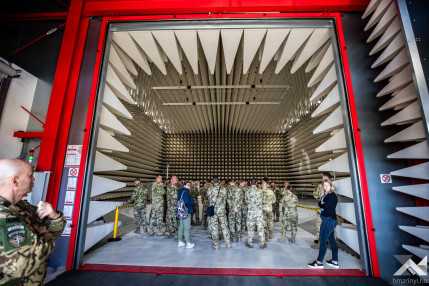

The third distinguished component of the company’s profile – besides production and development – is testing. The test tracks of the premises built for this purpose are varied and thus contribute to spotting all kinds of developmental or technical malfunctions before handover. Besides mobility testing equipment, climatic chamber, EMC chamber and underground life-saving firing tunnel tests are also used in the plant in Zalaegerszeg to guarantee the highest quality possible.

“It was good to hear that other military equipment is planned to be produced and developed here in the future. I think that it will only benefit the Hungarian Defence Forces” – said Private Csaba Walter summarizing the visit. He also mentioned that his application to the Lynx pilot program was primarily motivated by the modernity of the fighting vehicle, therefore, the fact that he is among the future operators of the combat vehicle type produced in Zalaegerszeg has added a lot to the experience of the factory visit.